2. Qaybta kontoroolka korontada

Khadka oo dhan wuxuu qaadanayaa habka xakamaynta mashiinka-mashiinka ee isku daraya PLC iyo shaashadda taabashada.Halbeegyada qeexitaanka, tirada iyo nidaamka qaybaha waxaa lagu dejin karaa shaashadda taabashada.Qaybo badan oo tilmaamaha hawlgalka ah ayaa la kaydin karaa hal mar.Heerka otomaatiga waa sarreeyaa.Waxay leedahay shaqeyn qaylo-dhaan ah haddii ay dhacdo cillad aan caadi ahayn oo ku jirta khadka wax soo saarka.Hawlgalka dhammaan khadka wax soo saarka ayaa lagu kormeeri karaa iyada oo loo marayo nidaamka xakamaynta.Korontadu xumaato ka dib ama xidhid aan caadi ahayn, ka shaqaynta waa la sii wadi karaa iyadoo la raacayo cabirrada shaqada ee hore loo dejiyay.

| Magaca | Summada |

| PLC | Mitsu |

| beddelka soo noqnoqda | Delta |

| Shaashada taabashada | Vinylon |

| Qalabka korantada ee hooseeya | Schneider |

| Xakamaynta Servo | Yaskawa |

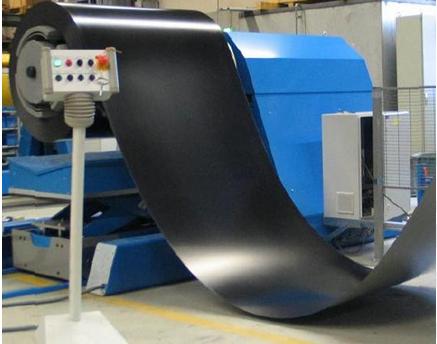

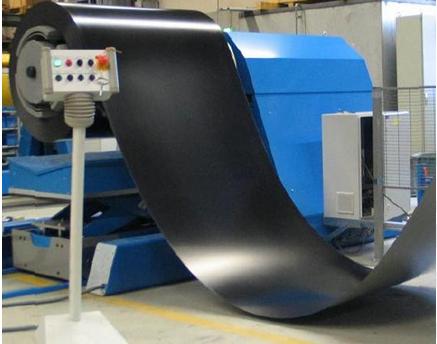

3. Qalabka kaydinta (silo).

Qalabka kaydinta wuxuu ka kooban yahay laba qaybood: rullaluistemadka qaabka arc iyo qalabka taageerada.Waxaa jira afar kooxood oo rollers-qaabeeya, kuwaas oo la dhigo labada dhinac ee labada haamood ee kaydinta.Waxay ka kooban yihiin fareemo qaanso ah iyo rullaallo dabacsan.Dusha rullaluistu waxay ku dhejisan tahay chrome adag.Dabool koronto-dhal ah ayaa lagu rakibay godka qashin-qubka si loo xakameeyo gelitaanka. Booska duubista walxaha godka, si xawaaraha qayb kasta oo ka shaqeeya uu si fiican ugu habboon yahay.